ZARGES MITRASET® RACKMOUNT CASES FOR MILITARY AND GOVERNMENT

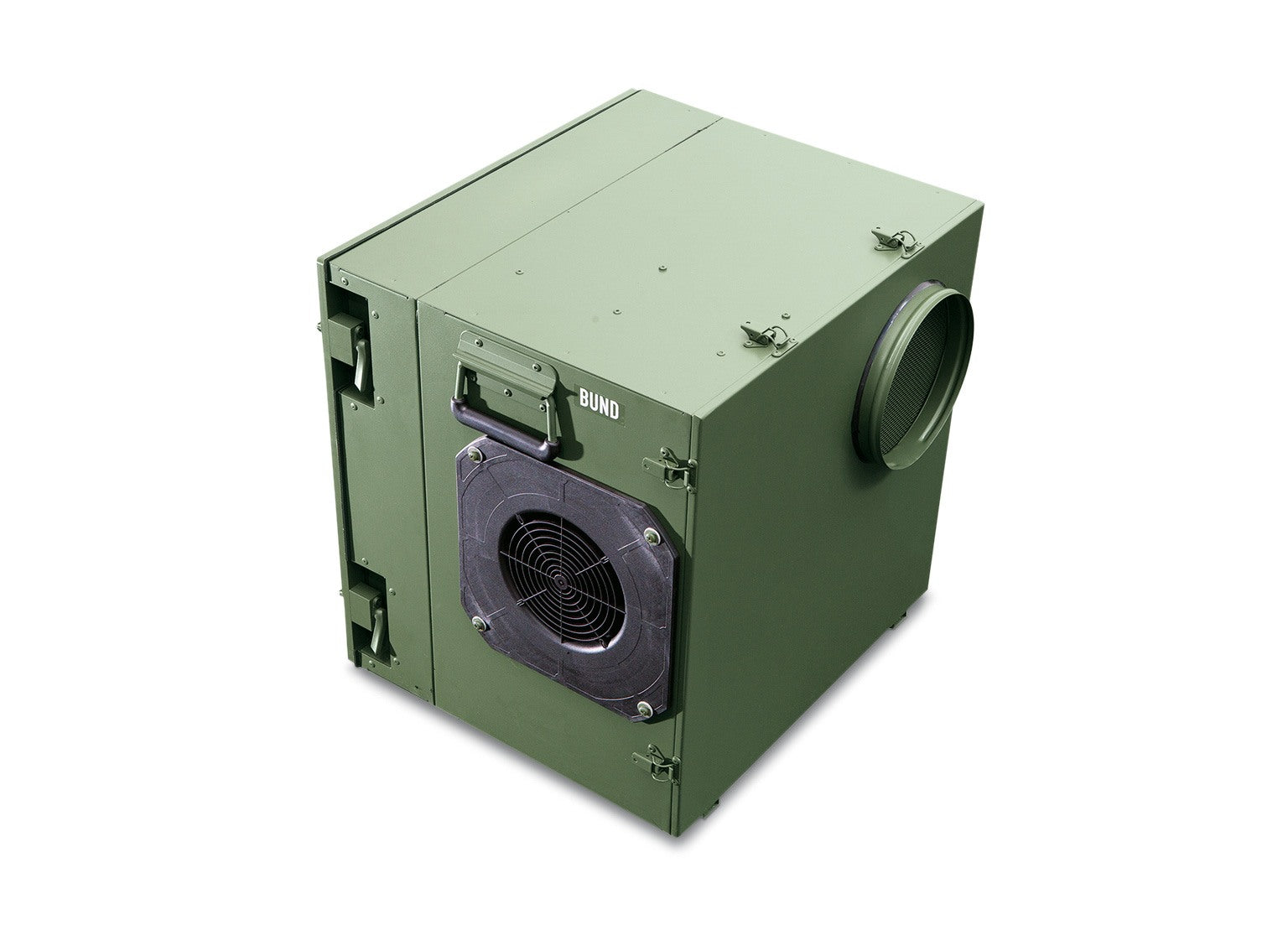

Mitraset aluminum rackmount cases are the number one choice for transporting highly sensitive electronic equipment. Whether for military, aerospace or industrial applications, Mitraset rackmount cases provide protection against moisture, shocks, impacts, vibrations and electromagnetic interference. With its Mitraset® Half Rack, Mitraset® RRF (Removable Rack Frame) and Mitraset® Racklite products, Zarges has genuine innovations to make handling even faster and simpler. Discover the multitude of applications and solutions provided by the Mitraset rackmount cases.

Mitraset Classic rackmount cases are made of aluminum and are designed to hold electronic equipment in a 19″ grid in accordance with DIN EN 60297-3-100 and EIA-310-E. Zarges Mitraset Half-Rack cases are designed to the same strict standards to hold half-size, 9.5″, electronics.

Mitraset rackmount cases have proven themselves in a multitude of tests and military deployments. For the Mitraset® Classic, Zarges has obtained US MIL-STD-810 standard.

MITRASET ALUMINUM RACKMOUNT CASE FAMILY

MITRASET CLASSIC

- Standard width for 19″ electronics

- For loads up to 220 lbs.

- Higher loads to be checked on a case-by-case basis.

- 3 to 22 U, nominal depth 8.62 to38.96 inches.

- Design according to VG 95 446 and 95 447.

- Complies with the highest military specifications.

- Individual design of damper elements according to customer specifications.

- Custom versions available.

MITRASET HALF RACK

- Half width for 9.5″ electronics

- For loads up to 110 lbs. Other payloads configured by request

- Available in standard depths up to 10U, custom sizes by request

- Manufactured in accordance with IP 65 rating

- Other custom options (dimensions, finishes, payload, etc.) available by request

MITRASET RACKLITE

- Standard width for 19″ electronics

- For loads up to 132 lbs.

- 3 to 12 U, nominal depths 13.78 to 30.00 inches.

- Commercially available rubber shock mounts with standardized (non-configurable) performance.

MITRASET RACKLITE BASIC

- Standard width for 19″ electronics

- For loads up to 132 lbs.

- 3 to 12 U, nominal depths 13.78 to 30.00 inches.

- Commercially available rubber shock mounts with standardized (non-configurable) performance.

- Same as Mitraset Racklite but without corner elements.

PROTECTION FEATURES

- Against mechanical loads such as shock, impact and vibrations.

- Protection against electromagnetic interference such as radio waves, lightning and general environmental influences such as heat, moisture and dust.

- The electronic equipment requiring protection is placed and fastened in place inside elastically suspended anti-vibration frames for optimal protection.

PRIMARILY FOR USE IN

- Military applications, telecommunications and the electronics industry

- Transport infrastructure such as rail security and traffic management systems

- Anywhere where sensitive electronic equipment requires mobile use or outdoor installation

ZARGES MITRASET MEETS OR EXCEEDS THE FOLLOWING STANDARDS

ATA 300

MIL-STD-810

- Method 500.5, Procedure I – Low Pressure (Altitude)

- Method 501.4 High Temperature

- Method 502.4 Low Temperature

- Method 505.4 Solar radiation

- Method 506.4, Procedure II – Water resistance, splash proof

- Method 506.4, Procedure III – Water resistance, drip proof

- Method 506.5, Procedure I – Rain and Blowing Rain

- Method 507.4 Humidity

- Method 508.5 Fungus

- Method 509.5 Salt Fog

- Method 510.4 Dust exposure

- Method 510.5, Procedure I – Blowing Dust

- Method 516.4, Procedure IV – Transit drop 1.2 m

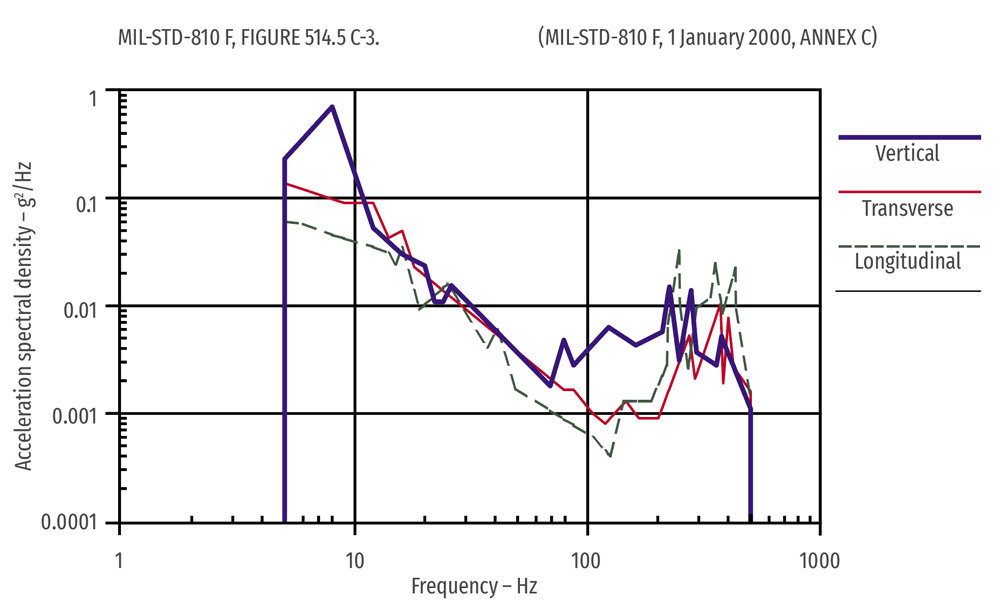

MITRASET CLASSIC – VIBRATION DAMPING

Unwanted mechanical vibrations often occur during transport and other situations. These may have a negative effect on the functioning of electronic components and thus represent an increased safety risk.

Mitraset rackmount cases offer a solution to vibration problems in military, aerospace as well as in industry applications. They are tested to MIL-STD-810.

For special requirements, a modified Mitraset rackmount case has been developed and undergone successful testing in accordance with the strict MIL-STD-810 F specifications.

ZARGES also develops customized solutions according to your specifications.

The diagram shows the test specifications according to FIGURE 514.5C-3.: Composite wheeled vehicle vibration exposure.

MITRASET CLASSIC – TESTS AND CERTIFICATES

These are important standards for military tests:

| Shock test | Test 516.3 in accordance with MIL-STD-810D-17 D-5. The shock test with recording of the damping values is to be carried out in six main directions, each with 3 half-sine shocks at an acceleration a = 40 g and a pulse time t = 7 ms. |

| Strength of carrying handles | The test specimen is suspended in the normal position and loaded in such a way that there is a force of 375 N acting on each carrying handle. The test sample is then suspended by each handle separately and a load of 750 N applied.

Duration of test: 5 minutes according to VG 95 446. |

| High temperature test | Test 501.2 in accordance with MIL-STD-810 D-3, method I A2. 24 hours, 71 °C. |

| Low temperature test | Test 502.2 in accordance with MIL-STD-810 D-4, method I C2. 24 hours, –51° C. |

| Temperature change test | Test 503.2 in accordance with MIL-STD-810 D-5. Method I to III, 3 × 4 h each time at 71 °C and – 50 °C. Damp heat test. Test 507.2 in accordance with MIL-STD-810 D-8, method III. |

| Vibration load | 1. Test 514.3 in accordance with MIL-STD-810 D-15, figures 514.3-7, 514.3-8 and 514.3-9, depending on the vibration axis, each 10 min. per axis.

2. Determination of resonance during random vibration according to paragraph 1. 3. Random vibration according to figure 514.3-36 in the three main axes, each one hour per axis. Paragraphs 1 to 3 to be carried out completely in one axis. |

| Salt spray test | According to MIL-STD 810 F method 509.4, 96 hours duration |

| Mildew formation | Resistance to mildew according to MIL-STD 810 F method 508.5, 28 days duration |

| Leak tightness | Test according to MIL-STD 810 G method 506.5 Rain – Procedure I – Rain and Blowing Rain. Wind speed 28 m/s, at least 90 minutes per side. Leak tightness according to IP 65 and DIN EN 60529. Dust and water-jet protection. |

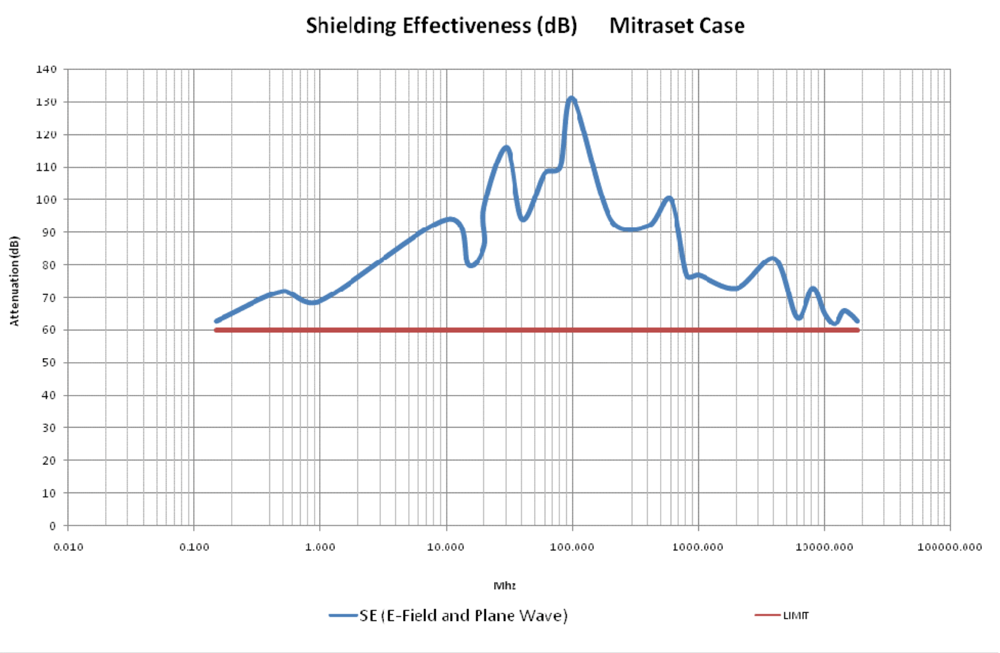

| Electromagnetic shielding | Shielding efficiency test in accordance with MIL-STD-285. |

| Testing according to specification of hazardous goods directive | Approval for the transport of hazardous goods, packaging group II in accordance with ADR / RID / IATA-DGR and IMBG Code. |

RF SCREENING

Mitraset rackmount cases made of aluminum have significantly improved RF screening properties compared with plastic cases. When required, these properties can be further improved through special measures.

ON CASES WITH CLOSED LIDS:

- By using a special lid seal.

- Opening through RF honeycomb filter, IP 54 shielding. Installed primarily in the lid.

ON CASES WITH OPEN LIDS:

- By fitting aluminum infill panels on 4 sides of the standard inner frame. Optionally perforated for better air circulation. In addition, the front and back of the frames are fitted with an RFI gasket.

- By fitting a flexible skirt seal made from conductive material between the outer case and the anti-vibration frame.

MITRASET CLASSIC RRF (REMOVABLE RACK FRAME)

On the new Mitraset Classic RRF (Removable Rack Frame), the 19″ anti-vibration frame can be removed quickly and easily without the use of tools, even with 19″ devices already installed.

When the anti-vibration frame has been removed, work on installed devices and cabling can then be performed quickly and easily due to the equipment being accessible from all sides. Rackmount cases with removable anti-vibration frames are used for prototypes and cases in which components need frequent removal and replacement.

A special surface coating ensures easy sliding of the anti-vibration frame. The rackmount case is equipped with a bonding (earthing) system as standard. The compact design means that the entire nominal height of the Mitraset Classic RRF is available as installation space.

Unlike similar products on the market, no rack unit space in ZARGES Mitraset rackmount case gets wasted through a locking system, and the outside dimensions remain unchanged.

Mitraset RRF have successfully undergone shock and vibration testing to MIL-STD 810 F, method 514.5. The Mitraset RRF with removable anti-vibration frames facilitates integration by allowing unlimited access to the 19″ slide-in modules.

Cables and plugs are easy to install. After completing installation, the entire anti-vibration frame is slid into the outer case and locked in place. Within just a few seconds, the rackmount case is ready for dispatch.

The Mitraset RRF is available only in the Mitraset Classic version.

WIRE ROPE SHOCK ABSORBERS

For particularly high loads or to absorb vibration, the 19″ frame featured on this variant is suspended on wire rope shock absorbers at an angle of 45°. The external dimensions have been increased correspondingly due to the increased size of the frame. This special version is available only for Mitraset Classic.

SPECIAL APPLICATIONS / CUSTOM SOLUTIONS

ZARGES provides you with the rackmount cases and solutions for a range of uses, e.g. in planes, in vehicles or for special deployments. These range from transport systems and rackmount cases with dampers through to dust and water protected as well as reinforced products for extreme conditions

The Mitraset 19″ rackmount cases offer a multitude of customized special solutions in addition to a large range of standard accessories.

HEAT MANAGEMENT

Mitraset 19″ rackmount cases offer the appropriate solution according to the application, the type of electronic equipment operated, ambient temperatures and the resulting air-conditioning requirements.

HEAT DISSIPATION IN WATTS UNDER VARIOUS OPERATING CONDITIONS

| Inner height | Nominal depth, in. | (1) Single case, free-standing watts | (2) Rear wall, attached watts | (3) Case in the middle of the stack watts | |

|---|---|---|---|---|---|

| 4 rack units | 8.54 | 82 | 66 | 56 | |

| 13.65 | 97 | 81 | 63 | ||

| 18.72 | 112 | 97 | 71 | ||

| 23.79 | 128 | 112 | 79 | ||

| 5 rack units | 8.54 | 91 | 73 | 65 | |

| 13.65 | 108 | 90 | 74 | ||

| 18.72 | 124 | 106 | 83 | ||

| 23.79 | 141 | 123 | 92 | ||

| 6 rack units | 8.54 | 101 | 80 | 75 | |

| 13.65 | 119 | 98 | 85 | ||

| 18.72 | 137 | 116 | 95 | ||

| 23.79 | 155 | 134 | 106 | ||

| 7 rack units | 8.54 | 110 | 87 | 85 | |

| 13.65 | 130 | 106 | 96 | ||

| 18.72 | 149 | 125 | 108 | ||

| 23.79 | 168 | 145 | 119 | ||

| 8 rack units | 8.54 | 120 | 94 | 94 | |

| 13.65 | 141 | 114 | 107 | ||

| 18.72 | 161 | 135 | 120 | ||

| 23.79 | 182 | 155 | 133 | ||

| 9 rack units | 8.54 | 130 | 101 | 104 | |

| 13.65 | 151 | 123 | 118 | ||

| 18.72 | 173 | 144 | 132 | ||

| 23.79 | 195 | 166 | 146 | ||

| 10 rack units | 8.54 | 139 | 108 | 113 | |

| 13.65 | 162 | 131 | 129 | ||

| 18.72 | 185 | 154 | 144 | ||

| 23.79 | 209 | 177 | 160 | ||

| 11 rack units | 8.54 | 149 | 115 | 123 | |

| 13.65 | 173 | 139 | 140 | ||

| 18.72 | 198 | 164 | 156 | ||

| 23.79 | 222 | 188 | 173 | ||

| 12 rack units | 8.54 | 158 | 122 | 133 | |

| 13.65 | 184 | 147 | 151 | ||

| 18.72 | 210 | 173 | 169 | ||

| 610 | 236 | 199 | 187 | ||

| 14 rack units | 610 | 263 | 220 | 214 | |

| 16 rack units | 610 | 290 | 242 | 241 |

DETAILS

The guide figures calculated in the table may be influenced by various factors:

Paint type and color

Internal air circulation

Location and position of the rackmount case

Influence due to adjacent rackmount cases

Weather and climatic conditions

Mitraset 19″ rackmount cases – customized solutions with air-conditioning

19″ rackmount case applications increasingly require air-conditioning. Zarges is therefore able to provide adaptable special rackmount cases for air-conditioning.

Cutouts for plugs, ventilation plates and the ZARGES heat exchanger lid complete the offer.

HEAT EXCHANGER LID

The Zargesheat exchanger lid ensures protection class IP 65 by means of 2 separate air circuits. Robust fans ensure that air is constantly circulated. Heat transfer between the two circuits takes place in a specially designed heat exchanger in the interior of the lid.

Heat dissipation depends on temperature conditions and on the location and position of the rackmount case. These solutions can be built by ZARGES according to customer specifications.

CUSTOMER EXAMPLES OF COOLING SYSTEMS

Air-conditioning units are combined with Mitraset only according to requirements. Transport takes place in in-house vibration-tested transport containers with customized foam inserts.