HISTORY

1933

FOUNDATION

On September 1st, 1933 a new, small company opens its doors in Hermannstraße 20 in the city of Stuttgart: Zarges Leichtmetallbau. Company founder Walther Zarges fulfils his dream of establishing a company that makes the day-to-day life easier for people through lightweight aluminum construction.

1938

MASS PRODUCTION OF LIGHT-METAL LADDERS

In 1938, Zarges becomes the first company in Europe to mass produce light-alloy ladders. The young company already has almost 100 employees at this point in time.

1939

RELOCATION TO WEILHEIM

By late 1939, the factory in Stuttgart is bursting at its seams. The constantly increasing number of orders and requirements imposed by the Federal government make relocating to a new building inevitable for the company, which is merely 6 years old at this point – Upper Bavaria is chosen as the new location.

1948

SERVICING THE “RAISIN BOMBERS”

The Allies place their trust in the experience of Zarges: the dismantled aircrafts are transported from the airfield in Erding to Weilheim for maintenance.

1951

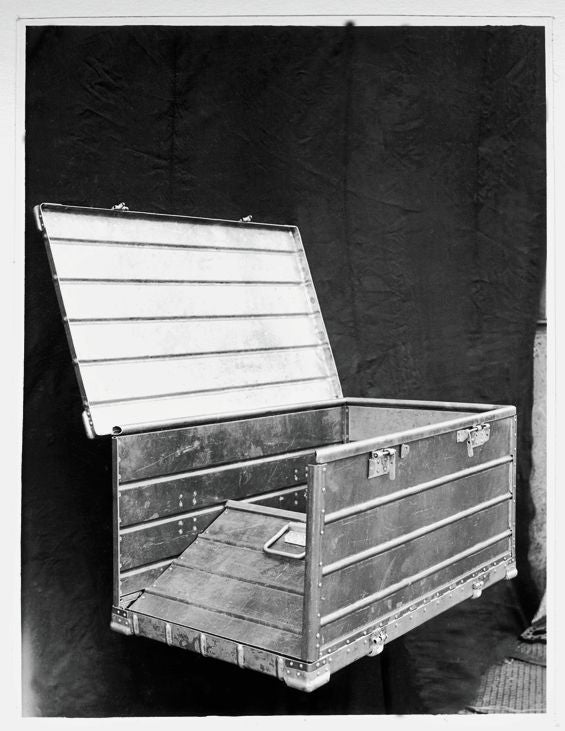

THE 100TH PATENT – THE ZARGES COLLAPSIBLE CASE

1951 marks the beginning of the mass production of aluminum collapsible cases. There are not too many trucks in the early ’50s. Goods are transported by rail, but the railway has too few carriages for the goods required in the country. The solution: the Zarges collapsible case. Not only does it help solve the problem of space, but it also is lighter than conventional packaging and, when empty, can be folded down to one sixth of its original volume. The dimensions of the Zarges collapsible case are in part still a standard in the industry.

1954

EXPEDITIONS IN ICE AND SNOW

Zarges supplies equipment for the first German-Austrian Himalayan expedition, providing cases as well as a few ladders. Many more people follow suit; globetrotters & extreme mountain climbers discover the advantages offered by ZARGES.

1958

25 YEARS OF ZARGES

In 1958, Zarges has 700 employees and is the oldest manufacturer of lightweight constructions in Germany. This, along with the Federal Cross of Merit bestowed on Walther Zarges, is naturally celebrated in a fitting manner.

1960

ZARGES DELIVERS A FARADAY CAGE TO THE DEUTSCHES MUSEUM

In the early ’60s, Zarges receives an enquiry from the Deutsches Museum. The museum wanted to exhibit what is known as a Faraday cage in order to demonstrate that electricity can be blocked by a continuous covering, leaving the covering’s interior protected from the electrical field. ZARGES designed and constructed the 2.25-meter-high sphere, which is used until today to illustrate to entire generations how the energy from a lightning strike is discharged.

1961

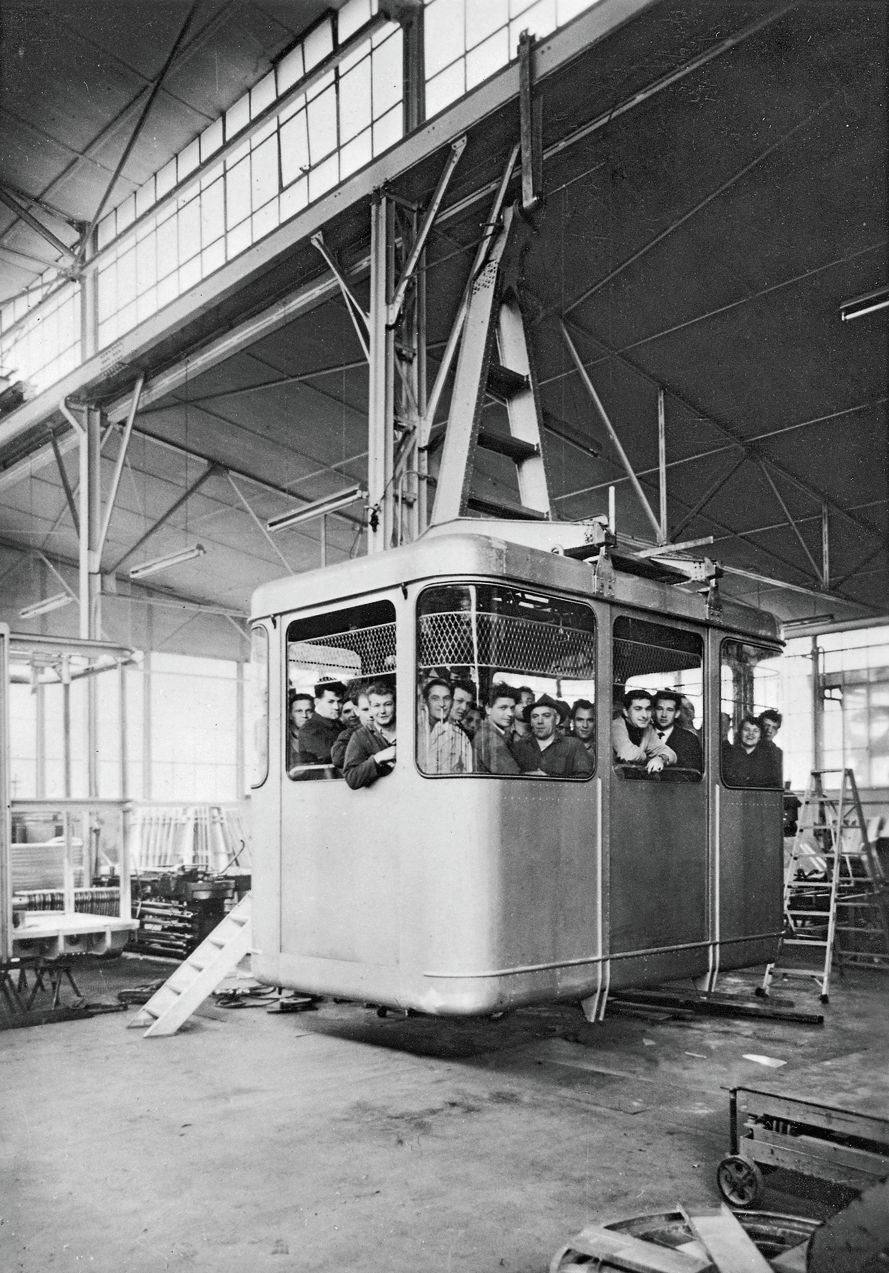

ZARGES CABLE CARS

In the early ’60s, Zarges begins constructing cable cars that can carry up to 70 passengers. The cars are used not only for the Zugspitze cable car system in Garmisch-Patenkirchen, but also in the entire Alps region. Futuristic ideas, such as a double-decker cable car, are also devised but never implemented. Even today, you can still find Zarges cable cars in use.

1970

USHERING IN COMPUTERIZATION

New computer systems, some of them as large as fridges and cumbersome to operate, have been used since the early ’70s in order to allow the company to work more efficiently and to improve its responsiveness. The first few computers are an important, albeit small, step towards integrated data processing. Zarges keeps up with the times and enters a new age in the company’s development.

1972

YEARS OF PROGRESSION

Setting off into a new age. In order to raise funds for the necessary factory expansions, the Zarges family sells part of the company to Vereinigten Aluminium-Werke, an aluminum production and processing company. The family-run industrial company becomes part of a national corporation. Zarges continues its upward trajectory with the introduction of high-quality flanging on ladders and with the “birth” of the ZARGES Box and new special constructions.

1978

THE ZARGES BOX – THE BOX FOR PEOPLE AND THEIR HOBBIES

During this time, there is increasing demand for products aimed at private use. Many people got to know the high durability and lightweight design of Zarges transport systems at their workplace and wanted to use them at home as well. Initially available in three sizes (Mini, Midi & Maxi), the Zarges Box becomes a global bestseller. Its introduction was accompanied by large-scale advertising campaigns in newspapers and television.

1984

RAISTING EARTH STATION

The aerial projects that Zarges implements in the ’70s and ’80s become increasingly larger and more complex. One of them is the Raisting earth station – still one of the largest terrestrial radio stations in the world today. Zarges was able to prove its ability during this project, because the parabolic aerials required extremely high precision. The reflector surfaces, which may be up to 30 m in size, were only allowed to deviate from their optimal shape by half a millimeter. “We owe our thanks to the outstanding accomplishment of Zarges.” – Werner Dollinger, German Federal Minister for Post and Telecommunications

1997

MERGER WITH FRENCH COMPANY TUBESCA GROUP

Through the merger with French company the Tubesca Group, Zarges becomes an international company and a market leader in the whole of Europe. Increased export ensures the company’s continued success, and new strategies help all divisions experience rapid growth – Zarges is now a global player.

2000

NEW FACTORY IN HUNGARY

In 2000, a new factory joins the ranks of the many factories owned by the Zarges TUBESCA Group: Kecskemét/Hungary.

2002

HOW DO I GET TO HOLLYWOOD PLEASE?

Zarges in Hollywood and everywhere else. Our boxes don’t just look good on screen. They not only were used in “Casino Royale” and “Die Another Day” as suitcases to carry money, but also provided the ultimate protection for the film crew’s equipment behind the scenes.

2004

A BOX SETS STANDARDS

The Zarges Box is featured in the book “Deutsches Standards” (English: German Standards) and join the ranks of products that helped write Germany’s history, alongside Tesa tape and Tempo tissue.

2007

Zarges established in US

2008

75 YEARS OF ZARGES

In 2008, Zarges turns 75 and our Indian subsidiary is founded. Although the markets keep becoming more and more international, one thing remains the same: Zarges continues to design and construct day-to-day aluminum products that are used everywhere in the world – much in the spirit of its founder.

2015

ERGO: ERGONOMICS

Introduction of the K424 XC mobile box office, easy-to-use cases characterized by their ergonomic handling. Work more easily and with less stress.

2016

BACK TO BASICS

Sale of the Tubesca Group and concentration on the core business. Zarges is now simply Zarges. A brand that stands for the highest quality and comprehensive solutions made of light metal.

2018

10 YEARS IN THE USA, ZARGES TURNS 85

It’s been 10 years since the Tech Center was established in Charlotte, NC. For 85 years and counting, Zarges has been delivering quality aluminum shipping and storage cases.

2018

ZARGES ACQUIRED BY PRoDriven

Since 2018, the ZARGES GmbH is part of ProDriven formerly WernerCo group. The worldleader for innovative safety solutions opens up a sales network in over 100 countries for Zarges and, with 5000 new colleagues around the world, fantastic synergies for the success of the entire group. https://www.prodrivenbrands.com

WHY ZARGES?

Lightweight

- Up to 50% lighter than comparable plastic cases

- Up to 70% lighter than traditional wood or road cases

Durability

- 2-7x greater tensile strength than plastic cases

- 5005 alloy aircraft grade aluminum sheeting

- Extreme temperature resistance from -228° to +302°

- Will not warp or crack

- Corrosion resistant

Optimized Space

- Up to 20% greater interior volume than plastic cases within a more compact footprint

- Custom sizes available to meet specific requirements

Specialized Features

- Over 50 standard size cases ready to ship the next day

- Wide range of accessories for mobility, security, organization, mounting

- Custom foam interiors

- Optional UN certification for hazardous materials

- IP54 protection standard, upgrades available to IP65 and IP67

lighter than other cases

greater tensile strength

greater interior volume

standard sizes available